Ashwill Industries – Ai2 Products was started in Hutchinson, MN in October of 2005 by Tony Ashwill.

It started as mainly a waterjet cutting shop and had a brand new Romeo Engineer Waterjet with a 5’ x 10’ cutting table show up at that time. Tony spent about 2 years putting this shop together and getting financing to get this all going. Quite a challenge to do considering he was driving truck during this whole period.

Tony’s History

Tony’s path to being a fabricator was not probably the usual path. He had been in the trucking industry for many years at this point and was needing a change. Tony’s dad had been a fabricator, machinist and designer his whole life and still does this for a local company to this day. Tony had been exposed to the fabrication world his entire life. During his trucking career he would leave the trucking world every so often for a couple years, working in a fab shop learning the different aspects of being a fabricator but the far majority of that skill came from his dad Larry! When Tony finally left the trucking industry in 2005 for good, he had over a millions miles logged and under his belt, an accomplishment he is proud of.

Tony’s path to being a fabricator was not probably the usual path. He had been in the trucking industry for many years at this point and was needing a change. Tony’s dad had been a fabricator, machinist and designer his whole life and still does this for a local company to this day. Tony had been exposed to the fabrication world his entire life. During his trucking career he would leave the trucking world every so often for a couple years, working in a fab shop learning the different aspects of being a fabricator but the far majority of that skill came from his dad Larry! When Tony finally left the trucking industry in 2005 for good, he had over a millions miles logged and under his belt, an accomplishment he is proud of.

In Feb of 1992, at the age of 21, Tony left the trucking world he entered the United States Air Force. While in the Air Force he was a Allied Trades Mechanic which was a vehicle body mechanic or body shop guy, but it entailed other skills as well such as welding, fabricating, glass repair, fuel tank repair, radiator repair, sewing and upholstery (believe it or not!). Tony was stationed at Hill AFB in Clearfield, UT which is just south of Ogden, UT. When they found out that he had a trucking background, he was able to do some truck driving during deployments out to the western desert of UT hauling equipment on a flatbed truck and also served as vehicle support during these deployments. He was in the vehicle maintenance shop at the Unit he was assigned to. Tony served there until 1995 and then entered the Air Force Reserves, moving back to MN and stationed out of the Minneapolis, St Paul Airport. He did this for approximately 2 years before being honorably discharged from the military.

When Tony was back to civilian life, the first job he had was at a stainless steel fab shop in Winsted, MN for a large dairy equipment manufacturer. He worked in this shop for about a year before the trucking bug hit him again. For the next 10 years, on an off, he was back to trucking, until the fall of 2005.

The Business Begins – Ai2 Products

The business started with a lot of hopes and dreams, but basically no customers. Tony states “Just so that everyone knows, starting a business from nothing is WAY more work than you would ever imagine (but if you knew then what you know now, you’d never do it either – so Ignorance is a bliss sometimes). The ball got rolling and it took a little time, but we welcomed our first customer and still work with this customer to this day. The first couple of years we were building up some steam and making progress until the bottom fell out of the economy toward the end of 2006 which lasted a couple of years. During that time period it was a challenge, but we got through it somehow!!!”

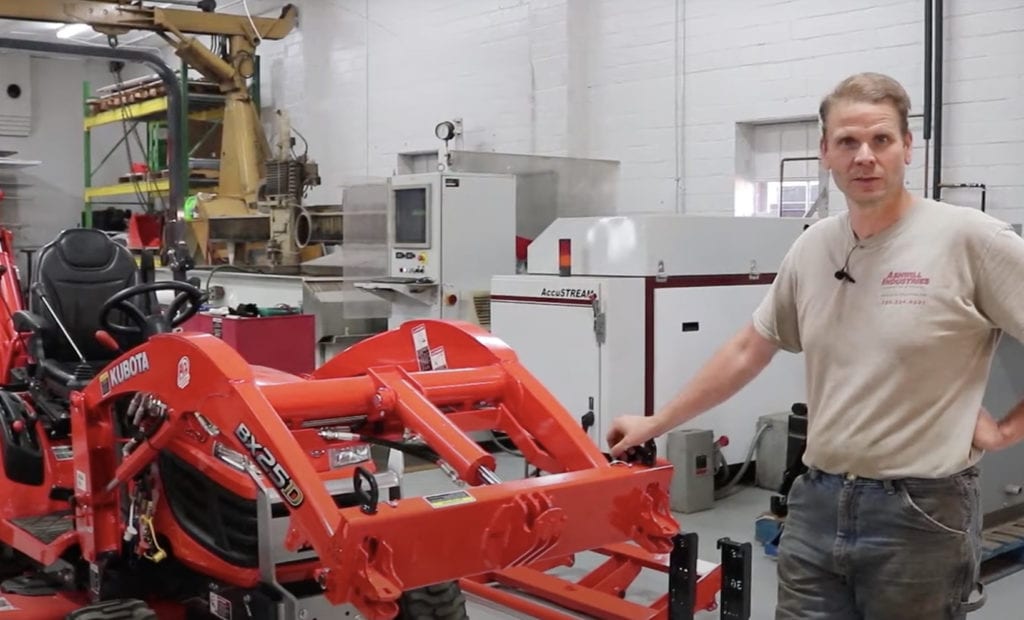

During 2008-2009 Ai2 Products came along and the whole Kubota BX product line began. Tony sort of fell into the Kubota BX product line more my accident that anything. A friend of his had a Kubota BX2350 and wanted a set of forks for it made and this friend knew Tony had built stuff for John Deere tractors on and off but nothing for Kubota. Tony and his brother Andy sat down to figure out what to do with that BX. Good thing Tony’s brother Andy was a designer and knew how to model things up. Andy went to work and designed up the very first pallet forks for the Kubota BX. They were just designed to pin directly to the loader and there wasn’t any sort of quick attach of any kind on the market for the Kubota BX. So they looked into it further and asked if they should come up with a quick attach as well. Andy quickly went to work and came up a with a design that was a little more tricky to get dialed in but was accomplished. Although Tony figured he would never build another one of these things again, he and his future wife Angela made a video showing the whole system and put it on Youtube. It was free to do and didn’t think anyone would care or even watch the thing. Well, that became a very popular video and he began to sell many sets of these things and decided that he needed to start a product side to the business, which became Ai2 Products. Ai2 Products stands for is Ashwill industries 2.

Ai2 Products was started along with Ashwill Industries, but only as a side thing for the most part since it only had the quick attach and pallet forks nothing else. Slowly other accessories started to get worked on and the product line started to grow. Tony was trying to do the Job Shop work with Ashwill Industries so in about 2010 a deal was put together with Jari USA out of (at that time) Mankato, MN. They would take over production and marketing of the of the current product line and Tony would continue working on coming up with new products to add. The deal wasn’t very successful so AI2 Products cut ties with Jari and was out of the Kubota BX products for about 4 years. Due to contractual agreements he could not produce anything for the Kubota BX. Around 2012 Jari USA was sold to another gentleman and Tony was able to retain the rights to his Kubota BX product line back. (So for those of you that knew about Jari USA you now know what the connection was with Tony and Ai2 Products. One of those lessons learned deals.)

Moving Forward

In 2014, Ashwill Industries Inc and Redline Manufacturing LLC got together to start a new business call Redline systems Inc. or RSI. Redline was and still is a skid loader, telehandler and wheeled loader attachment manufacturer. Together, Redline’s owner and Tony brought the job shop and compact tractor attachments side together with Redline MFG to start RSI. Tony worked in with RSI from 2014 till the spring of 2016 when a mutual decision was made to split RSI and Ashwill industries / Ai2 products back off into the two separate companies they were. For that reason, Kubota BX products may be seen out there with the RSI logo cut into them and info on the internet can be found about the BX products still falling under the RSI website yet. The Ai2 Products line has been brought back in full force allowing Tony to work on several new products to add to the BX product line. Currently, all Ai2 Products specializes in Kubota BX products. The experience with RSI was a good one and it brought a lot of insight into the attachment world and was really a great experience in the end for Tony. The split between RSI and Ashwill Industries / Ai2 Products went well and they still have a good working relationship with RSI.

In 2014, Ashwill Industries Inc and Redline Manufacturing LLC got together to start a new business call Redline systems Inc. or RSI. Redline was and still is a skid loader, telehandler and wheeled loader attachment manufacturer. Together, Redline’s owner and Tony brought the job shop and compact tractor attachments side together with Redline MFG to start RSI. Tony worked in with RSI from 2014 till the spring of 2016 when a mutual decision was made to split RSI and Ashwill industries / Ai2 products back off into the two separate companies they were. For that reason, Kubota BX products may be seen out there with the RSI logo cut into them and info on the internet can be found about the BX products still falling under the RSI website yet. The Ai2 Products line has been brought back in full force allowing Tony to work on several new products to add to the BX product line. Currently, all Ai2 Products specializes in Kubota BX products. The experience with RSI was a good one and it brought a lot of insight into the attachment world and was really a great experience in the end for Tony. The split between RSI and Ashwill Industries / Ai2 Products went well and they still have a good working relationship with RSI.

Tony has lots of plans and Ideas for the future of the BX product line and looks forward the next big product idea!

Contact Tony