Water Jet Cutting

We have a Romeo Engineering 2.5 axis, 60K abrasive water jet table with a 60″ x 120″ cutting envelope. With this machine, we can cut up to just about any type of material out there. We have cut up to 4″ thick mild steel and 6″ thick aluminum. Then all the way down to .005″ sst shim stock. An extremely versatile machine for the job shop world. Just send over a DXF or DWG file for a quote.

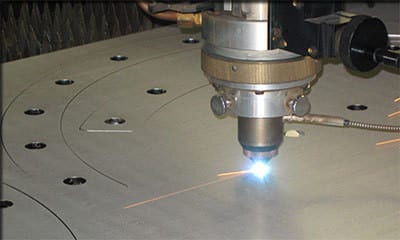

Laser Cutting

At Ashwill Industries we have a company we partner with to handle our laser cutting needs and our customer’s needs. We have access to 6000-watt CO2 machine capable of cutting up to 1.5″ T1 plate and a 5000 Watt Fiber machine capable of cutting up to 1.25″ T1 plate. Both machines have an 84″ x 163″ cutting envelope.

Welding

We utilize both MIG and TIG welding depending on the application and project. We specialize more in mild steel welding and run both short arc and pulse MIG machines. For our short arc or standard MIG welding, we use a Millermatic Vintage. Our pulse MIG machine is a Millermatic 350P. Our tig machine is a Lincoln precision tig 185. Both the pulse MIG and TIG machines are capable of welding aluminum. Give us a call and we’ll let you know if we can handle your project.

Metal Forming

At Ashwill Industries, we have a partnering company we work with to handle our oversized forming for our job shop customer’s needs. This CNC press brake has a 14’ bed with 363 tons of press capacity. We also get material rolled when needed.